IFAS’ institute mechanical design expertise to join ALPHEUS’ RPT design

The ALPHEUS’ project WP2 involves the design and manufacture of a pump/turbine runner that can work in low head conditions and with high round-trip efficiency. Within the project there are several partners from European universities, a company (Advanced Design Technology Ltd.) and a research organization (IHE Delft). The proposal of the project describes briefly all the necessary actions that need to be taken to carry on the project in an organized way. As a key activity within the project, an analysis revealed the need to address an additional research aspect, that is the adaptation and innovation of a suitable mechanical engineering design of the runner housing, gears, bearings, and seals. This activity through performing the mechanical design of the shaft driven Contra-Rotating Reversible Pump-Turbine (CR RPT) will provide a design layout for further manufacturing.

With respect to the RPT design, ALPHEUS included the deliverable “D2.1 SDCR model design”. In this deliverable, the wet surface of the runners is obtained from CFD analysis. On the other hand, the milestone “MS7 Manufacture and setup completed” includes the manufacturing of the turbine/pump. Upon start of the collaborative project, no specific partner was dedicated to the task of developing a mechanical design from the wet surface obtained in D2.1. As a consequence, the manufacturing of the pump/turbine could not have taken place and a remedy was required.

To solve this, a couple of avenues were discussed, including asking help from students, and through tying in expertise from early career researchers or involving external subcontractors. However, after carefully reviewing the options, an internal addition to the consortium partners was approached and eventually integrated into the ALPHEUS team. ALPHEUS is proud to announce the commitment of the IFAS of TU Braunschweig, the Institute of Jet Propulsion and Turbomachinery of the Faculty of Mechanical Engineering.

The Institute of Jet Propulsion and Turbomachinery (IFAS) headed by Prof. Dr.-Ing Jens Friedrichs is located in the north of Braunschweig at the research airport. The organization of the IFAS is divided into three working groups (Propulsors, Turbomachinery, Aerodynamics & Performance and Hydraulic Fluid machines Components & Seals). Further details and research topics of IFAS can be found at www.ifas.tu-braunschweig.de/en.

The experience that IFAS brings to ALPHEUS and in particular to the mechanical design of the RPT unit is strong. The “Hydraulic Fluid Machines: Components & Seals” working group of Dr. Schwarz deals with these topics within the institute, having previously designed turbines for tidal energy and designed and tested conventional pumps. Together, Prof. Friedrichs, Dr. Schwarz and Jonas Oldeweme (PhD student) will work on the ALPHEUS project, always in close exchange with the LWI and all other project partners.

An example of this experience is the research of Stefano Tosin in 2016. He focused on the topic “Counter-Rotating Mixed-Flow Pumps Design and Analysis”. Since this work is about the design of counter-rotating impellers, important principles for the mechanical design in ALPHEUS can be gained. The aim of this project was to investigate the power-density enhancement, which can be performed by adding a counter-rotating mixed-flow impeller upstream to a centrifugal impeller. Several counter-rotating mixed-flow pumps were developed and both numerically and experimentally tested. Under the same operation points conventional pumps (designed for the same flow capacity, speed and casing) were also numerically and experimentally investigated, in order to access the advantages of counter-rotating impellers.

Besides this project, there are two large pump test rigs located in the “water laboratory” of IFAS. The content of the research and industrial projects is, in addition to the increase in efficiency, the determination of the characteristic diagram, the stabilization of the characteristic curve, the development of runners, the verification of the feasibility of guidelines for centrifugal pumps and validation measurements for industrial test rigs. Figure 1 shows the large “DN500 test rig“.

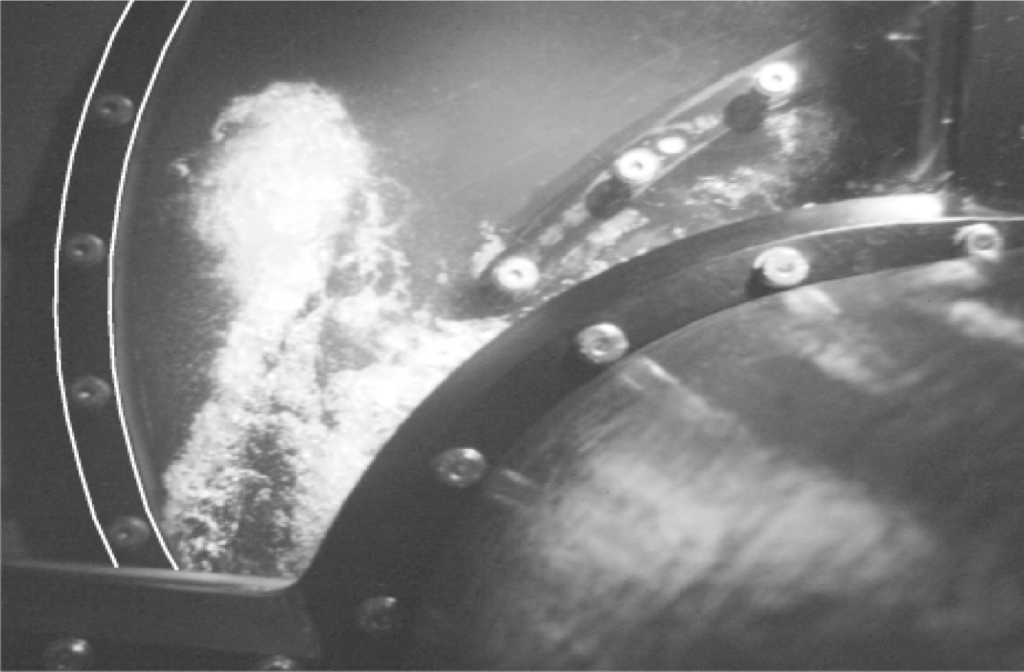

In the test rigs, relevant parameters can be determined, such as the water pressure on the suction and pressure side of the pump, the delivered volume flow, the temperature in the test circuit and the oxygen content. Transparent piping elements allow visual observation of tests on cavitation, as can be seen in Fig. 2.

A visual inspection of the two runners in ALPHEUS is also planned. Through many years of research in this field, as well as many scientific papers, IFAS can use its experience to progress ALPHEUS and provide an RPT mechanical design.

Jonas – PhD student at IFAS, in charge of developing the mechanical design.