Challenges to Face in Building the ALPHEUS Pump / Turbine Model

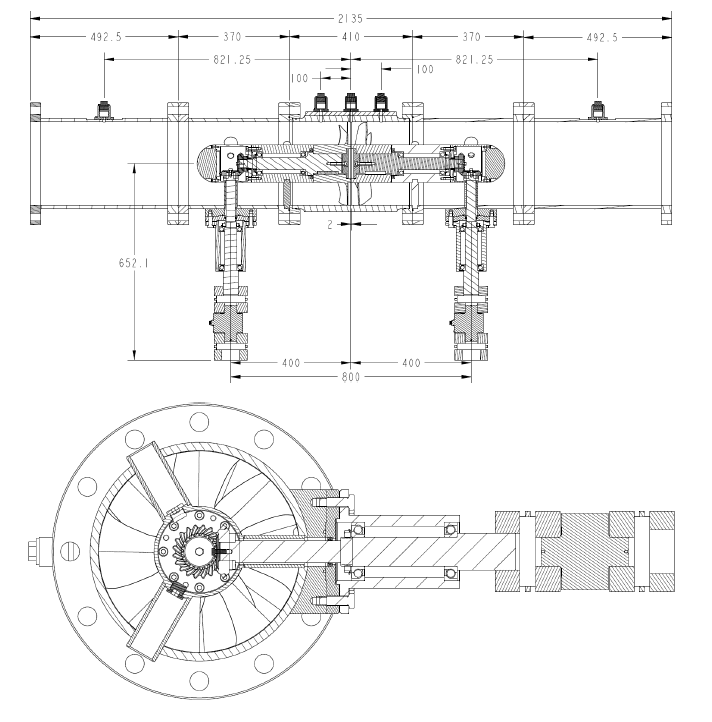

One of the biggest challenges during the mechanical design of the pump / turbine was to combine the wishes and goals of the consortium with the manufacturing and mechanical limitations. At the largest operating points of the design, very large torques are generated compared to the size of the design. The transmission of the torque through the bevel gears represents the most critical point. The space available at this point is particularly small, since all components must not be larger than the body of the runner. Due to their operating principle, the bevel gears require a particularly large amount of space. This trade-off between size and torque was a particular challenge during the design process. In order to cover both aspects, special solutions and approaches were necessary, in which IFAS could and had to contribute its many years of experience in the field of prototype engineering.

Furthermore, not only manufacturability but also the assembly had to be considered during the design. Due to the limited installation space and because a hollow tube is located in a pipe, which must be sealed, a strict sequence is required during assembly.

What do you hope to learn from the measurements taken on the completed model?

First and primarily, the experiment should provide data that our colleagues can use to validate their CFD simulations. To reach this goal, the measured values should be reproducible and consistent. Furthermore, the different positions of the measurements should provide insights into the flow and the runners.

ABOUT THE AUTHORS

Head of the Institute of Jet Propulsion and Turbomachinery (IFAS) is Prof. Dr.- Ing. Jens Friedrichs. In ALPHEUS he leads the working group dealing with the mechanical design of the RPT unit. Due to his many years of experience he gives important input in meetings and in all decisions.

Dr.- Ing. Heiko Schwarz is the head of the Research Group “Hydraulic Machines: Components & Seals”. With his many years of practical experience in the field of pumps, he contributes to the mechanical design of the RPT unit in ALPHEUS.

Jonas Oldeweme is a PhD student at IFAS. He is responsible for the design and construction of the RPT unit in ALPHEUS. In close coordination with the Leichtweiß-Institute for Hydraulic Engineering and Water Resource , he creates the CAD design. This involves creating drawings for manufacturing, parts lists and assembly instructions to ensure a smooth transition between IFAS and LWI.