CFD Validation Tests for the Reversible Pump Turbine

Today’s Reversible Pump Turbines (RPT) are not efficient for low-head applications like the ones present in the low-head Pumped Hydro Storage (PHS) stations. Furthermore, the pump-turbines installed in low-head PHS stations will have to deal with significantly variable head differences. That is why the ALPHEUS project is researching on the design of RPTs efficient for a range of low-head differences (≈5 m. to 20 m.). Using physics and the available past knowledge, several RPT geometries must be tested to see which configuration works best for the variable low-heads. Nowadays the use of CFD allows to do this in a computational environment, avoiding then the manufacturing of multiple RPTs to be tested on real conditions and thus the costs this entails. However, to make sure that the CFD model works as a manufactured model would do, a so-called validation is needed.

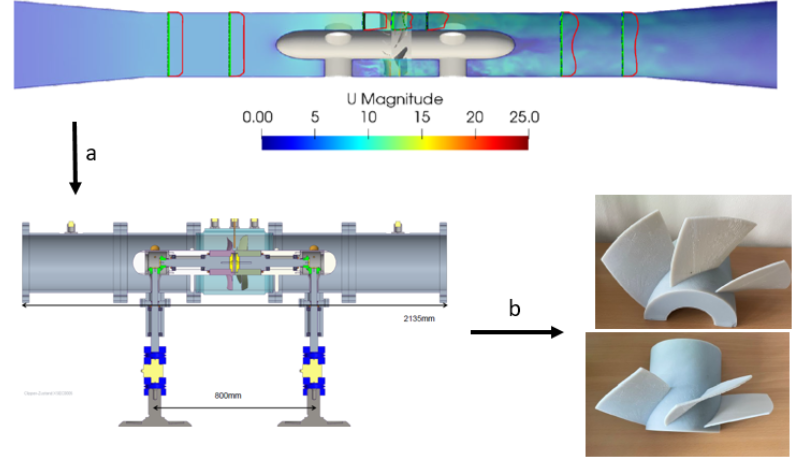

A model validation is the process by which a model is tested in real conditions to confirm that the model predicts the on-field results. To do that, first a CFD model was developed by Chalmers University of Technology and Advanced Design Technology, Ltd. This model includes an efficient RPT geometry. To manufacture this RPT unit, a mechanical design was performed by the Institut für Flugantriebe und Strömungsmaschinen (in English, Institute of Flight Propulsion and Turbomachinery) of the Technische Universität Braunschweig. Later, the RPT unit will be manufactured at the Leichtweiß-Institut für Wasserbau (LWI) (in english, Leichtweiß-Institut of Hydraulic Engineering) of the same university. Once the RPT unit is manufactured, it will be included within the newly built test setup of the LWI developed for testing the RPT unit.

From the test setup, data about water velocities and static water pressures can be obtained in regions next to the runners. Data will be taken at steady state for multiple head differences and discharges. Additionally, the data from the start-up and shut-down sequences will also be recorded. This data will be compared to the data of the CFD model to compare how well the model represents reality. It is expected that in the beginning, some changes to the CFD model will have to be made to adjust the CFD model values (of speed and pressure) to the ones obtained at the laboratory. After some iterative rounds, the model will reproduce reality with great precision. At this point, the model is said to be validated and thus it reproduces reality. Then, the model can now be used to iteratively change the geometry of the runner to find the most efficient configuration.

.

ABOUT THE AUTHORS

Since 2018 Nils Goseberg is the professor of hydromechanics, coastal and ocean engineering, heading a division of the Leichtweiß-Institute for Hydraulic Engineering and Water Resources. Additionally, he is the deputy director of the Coastal Research Center (Forschungszentrum Küste), a joint research facility of Technische Universität Braunschweig and Leibniz University Hannover. His expertise is towards experimental, numerical and analytical research in hydraulic, coastal and ocean engineering, having interests in wind-waves, tsunami engineering, coastal protection, sediment transport and offshore aquaculture and marine renewables, among others.

Since June 2020, Ruben Ansorena Ruiz is a PhD student at the hydromechanics, coastal and ocean engineering department of the Leichtweiß-Institute for Hydraulic Engineering and Water Resources under the supervision of Nils Goseberg. After studying civil engineering at Universidad de Cantabria, he completed a MSc at Technische Universiteit Delft in the field of Hydraulic Structures and Flood Risk. The development of his MSc thesis on the conceptual design of a Low-Head Pumped Hydro Storage Station for the DELTA21 plan, enhanced his interest in large-scale renewable energy storage which then lead him to join the ALPHEUS project.

Ruben and Nils are mainly contributing in Work Packages (WPs) 2, 4 and 5. Within WP2 and WP4, they are working on the design and construction of a brand new test setup for testing the Counter Rotating Reversible Pump Turbine (CR RPT) within the Leichtweiß-Institute for Hydraulic Engineering and Water Resources. This includes manufacture of the CR RPT in-house and the installation of the necessary hydraulic, electric and data acquisition equipment to test the machine in both turbine and pump mode. The tests will be done with discharges of up to 500 l/s in turbine mode and up to 330 l/s in pump mode, having an available head difference between 7.15 and 8.45 m.

Regarding WP5, they are developing two different stakeholder analysis to inspect:

- Stakeholder concerns: This will be conducted in the end of 2021 and during 2022 to describe the ALPHEUS project to the stakeholders and to analyse the concerns of them respecting ALPHEUS. Additionally, the stakeholders can give their view of where a Low-Head Pumped Hydro Storage Station should be placed.

- Stakeholder capabilities: This will be conducted in the end of the ALPHEUS project. The Stakeholders will have the opportunity to see the technologies developed by ALPHEUS and decide if they will invest in or can manufacture/construct this technology.