Update on ALPHEUS Work Package 3

In WP3, the Power Take-Off (PTO) and machine-side control are studied and designed. One part of this work package deals with rotor fatigue.

One of the overarching aims of the ALPHEUS project is to show the viability of using low head pumped hydro to improve the stability of the grid. One of the means to improve grid stability is to provide Frequency Containment Reserve (FCR). When the gird frequency deviates from its nominal value, the power output of the Reversible Pump-Turbine (RPT) is changed accordingly.

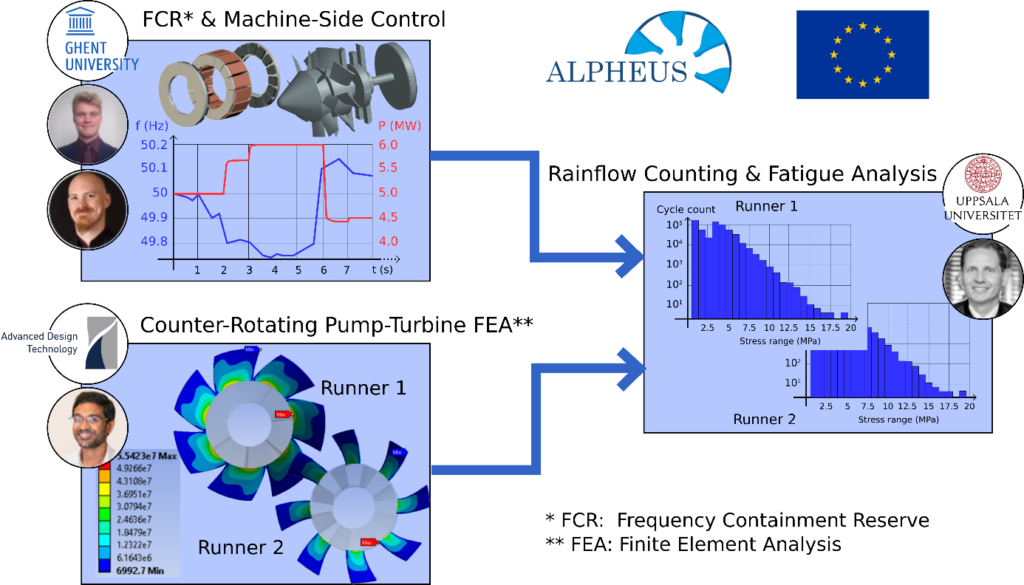

Changing the power output of an electric machine inevitably leads to time-varying mechanical stresses and thereby additional fatigue on various parts of the system. In order to quantify this extra fatigue in the RPT, FCR capacity and machine-side control architecture, a detailed methodology has been developed. This methodology has resulted in a close collaboration by different partners of the ALPHEUS project.

- At Ghent University, a machine-side control architecture is developed that lets the RPT reach a power setpoint fast and efficiently. Next, the FCR capacity is defined, which results in a power setpoint that changes with the grid frequency. To allow fatigue simulation over a multi-year period, a fast surrogate model of the machine-side control is created. Using historic frequency datasets of the European grid, the machine-side response of the FCR providing system is simulated.

- At Advanced Design Technology (ADT), Finite Element Analysis is performed to find the magnitude and locations of the maximum stress points of the RPT propellers. Multiple operating points that are found from the machine-side response are analysed.

- Combining the machine response to the grid frequency and the maximum stresses at these operating points, the stochastic stress cycles in the RPT are found versus time. To analyse the different stress cycles and perform fatigue analysis, Uppsala University developed a methodology using rainflow counting to analyse the stochastic stress-time series.

In a first analysis using the described methodology, it is found that using the RPT to provide FCR with 1 MW capacity while constantly generating 5 MW, the stress levels are lower than the infinite-life limit of the material. However, the developed methodology allows to repeat this analysis for different RPT designs, FCR capacities and control architectures.